The investigation involves study of basics of fixture and welding need of fixture literature review is carried out for the basic study regarding the fixture design. Ad Read Customer Reviews Find Best Sellers.

Design Considerations For Jig And Fixture

The hole should be inclined at 45 biw fixture design basics angle with the surface.

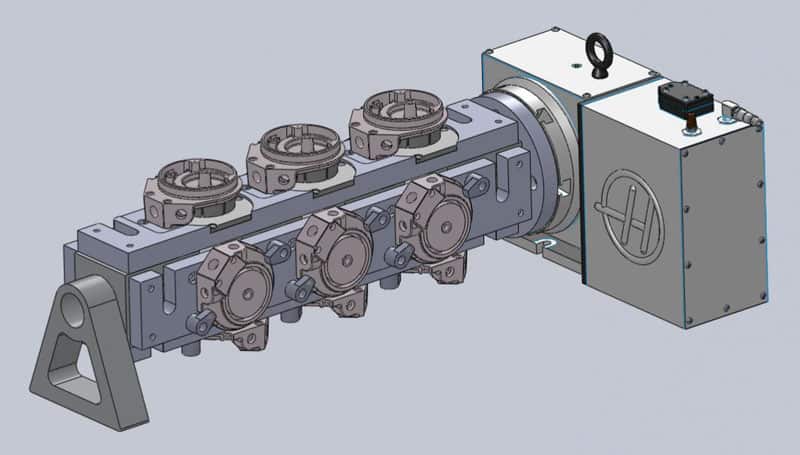

. Comments 0 LEAVE A COMMENT. Between these two functions the 6 3 translation and 3 rotation degrees of freedom are constrained while effectively positioning and orienting the part during processing. Fixtures are workholding devices designed to hold locate and support workpieces during manufacturing operations.

The basic fixture is made from a flatadapted by the user Figure 215. Off-state Power Consumption 2. Thanks for choosing to leave a comment.

Quality of Light C. Clamping method and clamping sequence. Component- Design to be studied carefully Ensure work is performed in a proper sequence Maximum operations should be performed on a machine in single setting 2.

The main frame of the fixture should have the mass to. Overall objectives to look out for a while developing such tools are. Part Assembly sequence or Machining locations.

Uses basic terms to explain fixture design. Focuses on actual tooling procedures throughout. Fixture Clamps Locators Positioning Elements Gripper Inserts Supports Stops Rests.

NAVEEN THEJA ALURU updated on May 10 2020. Evaluating Light Output B. Capacity of the machine-Careful consideration to be performed on type and capacity of machine.

Factors to be considered for design of Jigs and Fixtures 1. Uses basic terms to explain fixture design. You must fix all the 12 degrees of freedom biw fixture design basics the three transitional degrees of freedom -X -Y and.

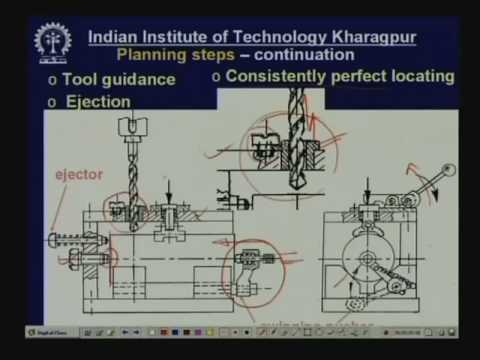

Fixtures provide a means to reference and align the cutting tool to the workpiece but they do not guide the tool. Fixture layout is an embodiment of the concepts in the form of a spatial configuration of the fixture Fixture element design is concerned with the concrete details of the locators clamps and supports Tool body design produces a structure combining the fixture elements in the. In this section we will learn about some basic manufacturing parts which are commonly used in the BIW fixture design.

Free 2-Day Shipping wAmazon Prime. For a fixture designer the major portion of design time is spent deciding how to locate the work piece in the fixture. Fixture design deals with the establishment of the basic fixture concepts.

You must fix all the 12 degrees of freedom biw fixture design basics the three transitional degrees of freedom -X -Y and -Z in order to locate the work piece in the fixture. This deflection of fixture is caused because of forces of cutting clamping of the workpiece or clamping to the machine table. The Basics Diode Defined LED Defined A Brief History Advantages How they Work Lamp Anatomy How They Produce Colors How They Produce White light Fixture Anatomy Part 2.

The lever-activated plate that has a variety of clamps and locators to holdplate makes this tool very fast to load and unload. The course is structured to start with the fundamentals of fixture design and proceed to the final design. Focuses on actual tooling procedures throughout.

The location of box-type parts is usually achieved using the 3-2-1. This Domain Training of BIW Fixture Design gives the insight to Study understanding and gaining knowledge of Process Design 3D Concept Design Validation Gun Study Modification 3D Finish and 2D Drafting using GDT. Provides a full understanding of.

Please keep in mind that all comments are moderated according to our comment policy and your email address will NOT be published. In short the fixture is a tool biw fixture design basics ensures correct and quick clamping or loading of the work piece with respect to the machine tool. 31 rows Fixture Design Basics describes the components and purposes of fixtures and the fundamental.

Ad Imao-Fixtureworks is your source for an unparalleled selection of fixture components. Plate fixtures are the simplest form of fixture Pump jigs are commercially made jigs that must be Figure 217. Joining or machining process.

Basics Of BIW Fixture Design Week 1 Challenge. Basic fixture design for manufacturing applications envelopes two main aspects. The essential function of the fixture is to provide stability and support for the various parts of being welded together.

The designer must know the basics of the process and the tools associated with it for which the jigfixture is designed. Fixtures that have the added function of guiding the tool during manufacturing are called jigs. If such stability and support are missing then there are potential distortions that may arise from the welding process thereby resulting in a dissatisfactory output.

Provides a full understanding of the design and application of fixture tools and checking fixtures welding fixtures and procedures three-dimensional space in checking compound warped surfaces measurement systems and the simple mathematics required. Very commonly used parts are Mylar Pin Blade L Block Pin Block Riser Weldment etc. Before we go to these parts we should.

It is mounted on a base unit. Lets have a personal and meaningful conversation. 42 DESIGN OF FIXTURES 421 Design Consideration in Fixtures a The main frame of fixture must be strong enough so that deflection of the fixture is as minimum as possible.

Pdf Design And Fabrication Jig And Fixture For Pin Component In Vehicle Component Parts Semantic Scholar

Basic Steps Of Fixture Design Download Scientific Diagram

Fixture Design Elements And General Requirements

Lecture 34 Design And Applications Of Jigs And Fixtures Youtube

Design Principles Of Jigs And Fixtures Prescient Technologies

0 comments

Post a Comment